Mining & Quarries

Extreme solutions for your extreme conditions

Find the right tire

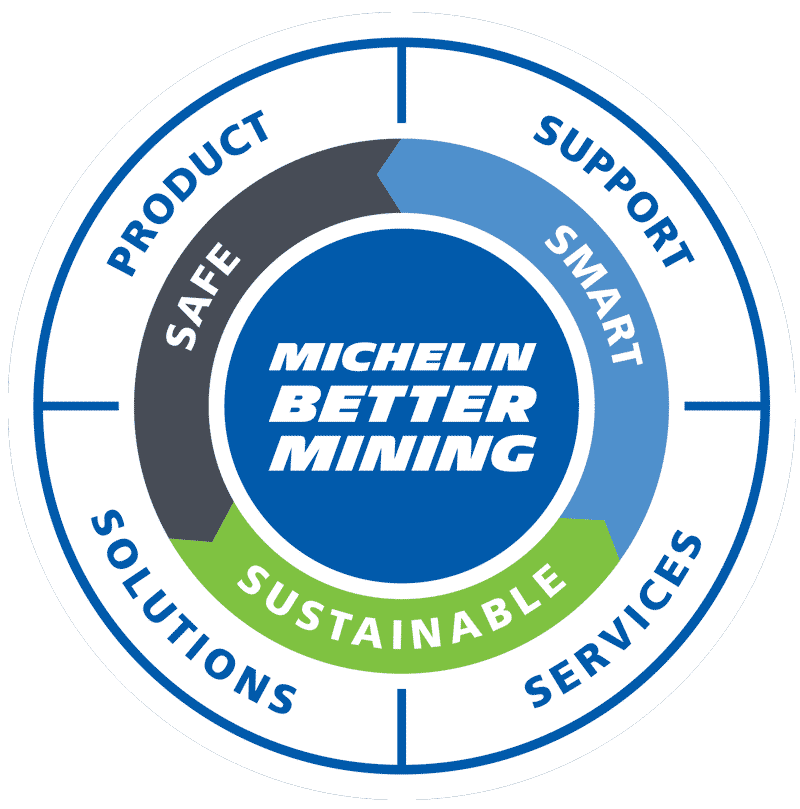

mbm infographic update full

INNOVATION THAT SUPPORTS YOUR GOALS

MICHELIN® Better Mining offers innovative solutions for safe, smart and sustainable mining. That means better earthmoving tires for all types of surface and underground mining as well as quarry machines.

Our priority is your safety and productivity. We accomplish that by focusing on MICHELIN Better Mining’s four key pillars:

PRODUCT

Michelin now has seven industrial sites dedicated to the manufacture of mining tires.

SUPPORT

Your expert product support team includes an account manager, customer engineering support and a MEMS® Service Engineer.

SOLUTIONS

Our solutions are based on proven technology and careful data analyses.

SERVICES

MICHELIN® Consulting & Services helps mines unleash their peak performance.

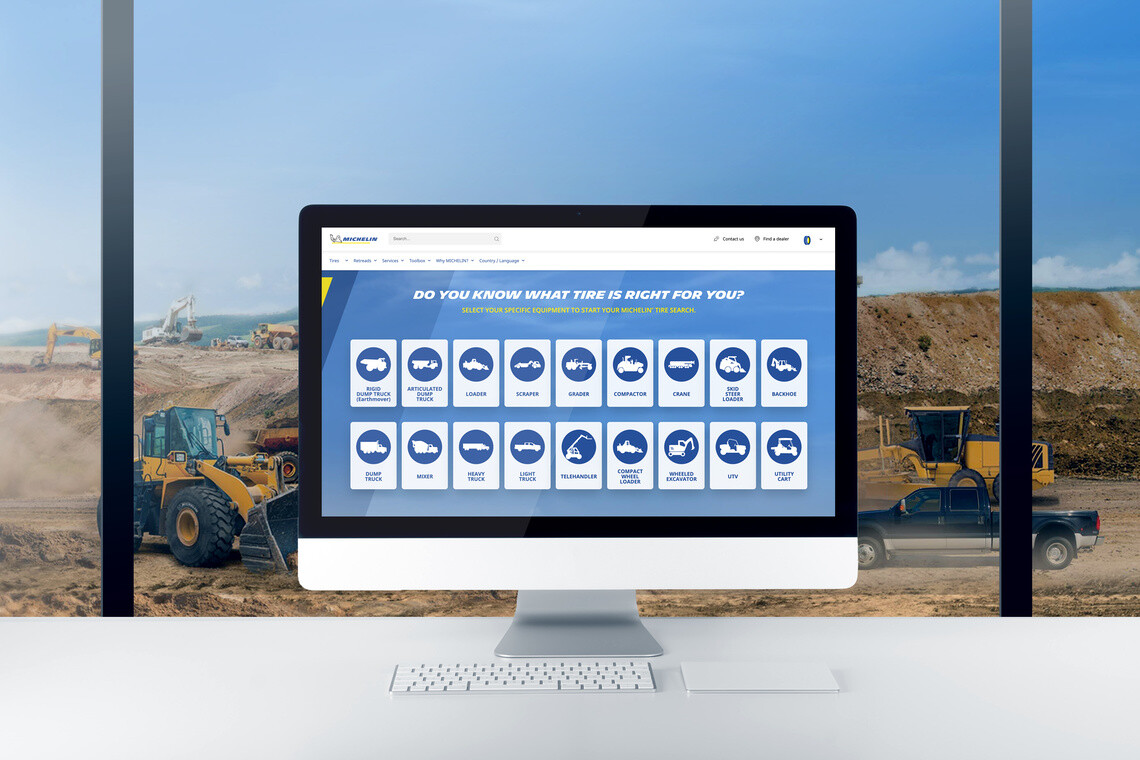

quarryboostmockup

THE RIGHT TIRES FOR ANY APPLICATION

Identify the right tires for mining, construction, turf care and everything in between. From standard to aggressive conditions and tweel to pneumatic, Michelin has the tires you need to get the job done.

Edito photo mining 7 Tire

edito mining underground tire

edito photo carriere tire

mems4 key visual purchased img

OUR SERVICES AND SOLUTIONS

All over the world, our customers have similar needs: to improve their productivity, lower their operating costs and improve the level of site safety for both people and equipment, all while preserving the environment.

To ensure that MICHELIN tires express their full performance potential, our teams provide you with their expertise, as well as tools to analyze and improve driving conditions on site. This makes it possible to adapt the choice of tires to your particular working conditions and optimize their use on a daily basis.

FEATURED TIRES:

TIPS AND TOOLS TO HELP YOU MAKE THE RIGHT CHOICES

Edito photo mining 4 Tire

CONTACT AN EXPERT

A question you haven't found an answer to? Write to us!